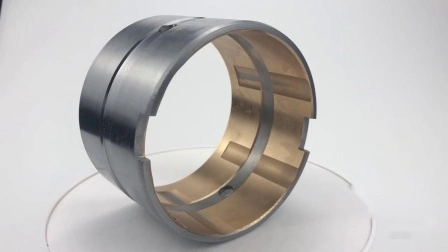

Dry-Running / Oil-Less Carbon Graphite Bearings in Pharmaceutical Industry

dry-running / oil-less carbon graphite bearings in Pharmaceutical Industry lttrade.en.made-in-china.com A: company profi

Send your inquiryDESCRIPTION

Basic Info

| Density | 1.75-1.9 G/Cm³ |

| Resistivity | Less Than 18 |

| Porosity | Less Than 26 % |

| Ash Content | Less Than 0.5 % |

| Compressive Strength | 40-80 MPa |

| Transport Package | Cartons in Wooden Cases |

| Specification | personalized customized |

| Trademark | L. T |

| Origin | Cn |

| HS Code | 3801909000 |

| Production Capacity | 250000/Month |

Product Description

dry-running / oil-less carbon graphite bearings in Pharmaceutical Industrylttrade.en.made-in-china.com

A: company profileOur facility is the biggest producer of graphite molds in North of China, which has over 15 years of experiences on graphite mold design and producing. With the reliable factory technical support and good after-sales service, our graphite molds have covered all china market. Now, combined with export experiences of L.T TRADE, Our products will be more complete and go further. Our major products now are: graphite plate, graphite crucible, graphite ring, graphite wire saw, graphite hot cutting pieces, graphite sintering diamond segment etc. And very welcome you provide drawings and designs, we can provide OEM and ODM. B: Why choose usGraphite mould plays a dual role in the process of manufacture: Heating element and Supporting mold. The quality of graphite mold is very important, will directly affect the next diamond tools' accuracy and appearance. So, which kind of graphite mold is suitable for sintering diamond tools:

- Good performance on conductivity and high rate resistivity

- Enough Mechanical Strength

- Good performance on Oxidation resistance

- Durable

- dense structure and low porosity

- Fined surface and low rate heat-deformation

- High mechanical strength and machining accuracy

- Oxidation resistance and durable

| Density g/cm³ | 1.75-1.9 |

| Resistivity μΩ·m | ≤18 |

| Compressive strength Mpa | 40-80 |

| Porosity % | ≤26 |

| Elasticity Modulus Gpa | 6-18 |

| Thermal expansion coefficient 10-6/ºC | 1.47-4.25 |

| Ash content % | ≤0.5 |

| Temperature resistance ºC | 4350 |