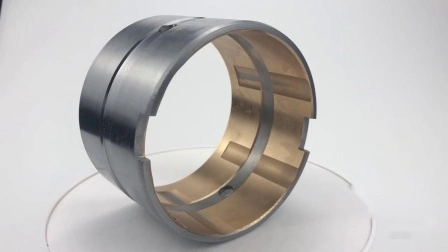

M-0260 Bronze Bushing for Iron and steel manufacturing/ Food processing/ Automotive

Package size per unit product 5.20cm * 5.40cm * 4.00cm Gross weight per unit product 0.060kg The bronze bushings are sel

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | M-0260 |

| Customized | Non-Customized |

| Certification | CE, ISO |

| Standard Parts | Yes |

| Universal | Yes |

| Type | Bushing |

| Material | Wrought Bronze, Copper plus Zinc |

| Lubrication | Self lubrication |

| Indent Surface | Finish |

| Transport Package | Industrial Packing |

| Specification | 50.9x52.5x38.1 |

| Trademark | GIL / Follow Customer′s requested/ Netural |

| Origin | China |

Packaging & Delivery

Package size per unit product 5.20cm * 5.40cm * 4.00cm Gross weight per unit product 0.060kgProduct Description

The bronze bushings are self-lubricating. It has a high tendency to carry heavy loads, It performs better than the other bushings due to its wear resistance and high potential.

Category:

- Bronze Graphite Bush

- Linear Bronze Bushing

- Linear Bronze Bushing

- Sintered Bronze Bush

- Solid Bronze Bushing

- Customized Bronze Bushings

Properties

- Red bronze is the most prevalent and cost-effective simple bearing alloy.

- It has good emergency functioning characteristics, as well as adequate wear resistance under medium loads.

- Unhardened shafts and light edge pressure are also suitable.

- It is a rigid bearing material with excellent gliding characteristics and wears resistance mainly when significant surface pressures and collisions co-occur.

- It has exceptional gliding characteristics, strong wear resistance, and heat resistance.

- With the self-lubricating ability and reinforced shafts, it can handle high speeds and weights.

- Especially well-suited to thin-walled bushings.

Bronze or comparable alloy bushings like most metallic bushings have stronger mechanical strength and PV values.

Advantages

- Wear resistance is good, the friction coefficient is low, and the service life is long.

- With the correct load capacity, the stress can be distributed over a larger contact area, increasing bushing capacity.

- The static and dynamic friction coefficients are near, ensuring the machine's operational accuracy.

- Can decrease vibration, reduce noise, avoid pollution, and improve working conditions in machines.

- To protect the grinding shaft, a transfer film might be formed throughout the operation.

- The hardness requirements for grinding shafts are minimal, which reduces the processing difficulty of associated parts.

You can reduce the mechanical volume by using a thin-walled, lightweight structure.

Application:

- Iron and steel manufacturing

- Food processing

- Injection molding

- Automotive machines

- Earthmoving machinery

- Pumps and other industries in low-speed, high-load, and severe-duty industrial applications and machinery.

Granville's advanced service solutions can help you to:*Improve productivity*Reduce maintenance costs*Improve energy efficiency*Optimize designs*Reduce time to market*Reduce total cost of ownership

Comprehensive product range:*Bearings*Oil seals, Transmission belt*Chain and Sprocket*Hub assembly & Wheel bearings*Coupling, castings*Linear motionValues* Behavior-based, service-oriented, focused on results, and committed to continuous improvement.Mission* Provide comprehensive quality products and thoughtful service

Related Products

-

![Jvb Professional Bearing Supplier Deep Groove Ball Bearing 6900 Brass Ball Bearing Cage 10*22*6mm]()

Jvb Professional Bearing Supplier Deep Groove Ball Bearing 6900 Brass Ball Bearing Cage 10*22*6mm

-

![Reducing Bushing Adapters Bearing Steel Arbor Hole Bench Grinding Wheel Accessorie]()

Reducing Bushing Adapters Bearing Steel Arbor Hole Bench Grinding Wheel Accessorie

-

![Hot Products Bronze Wrapped Bearing Split Bronze Bearing Without Oil Groove]()

Hot Products Bronze Wrapped Bearing Split Bronze Bearing Without Oil Groove

-

![Bimetal Sleeve Bimetallic Shaft Sleeve Split CamShaft Bushing]()

Bimetal Sleeve Bimetallic Shaft Sleeve Split CamShaft Bushing