Elastomeric Polymer Alloy Composites for Hydro-Turbin Bearing, Water Lubricating

INDRON® - hRBR: Water Lubricated, Wear-Resistant, Flame-Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant The su

Send your inquiryDESCRIPTION

Basic Info

| Other Material | Ceramic, Wood |

| Trademark | INDRON |

| Origin | China |

| Production Capacity | 10000 |

Product Description

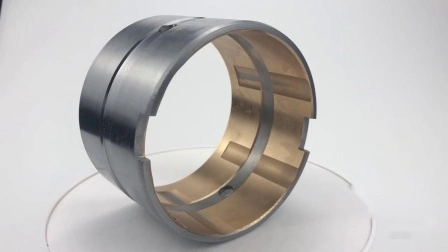

INDRON® - hRBR: Water Lubricated, Wear-Resistant, Flame-Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant

The surface hardness of INDRON® hRBR is relatively low. Giving way to the burial of abrasive grains and transferring them from the friction pair to the water tank to discharge them can guarantee the most wear-resistant grade in INDRON® elastoplastic alloy. The performance remains excellent in the medium of high sediment content.

COMMON GUIDE BEARING MATERIALS

| Bearing type | INDRON bearing | AR bearing | Ceramic bearing | Rubber bearing | Babbitt alloy bearing |

| Characteristics | The performance is close thordon, which can use more equipment assembly methods. In addition to traditional installations by freezing and pressurizing. It can also be installed by coating reactive thermal polymerization Dx and cold sticking. | Good wear resistance and impact resistance. The bearing hardness is high; the shaft sleeve is easy to wear; the temperature difference changes greatly; there will be the risk of shelling; the price is high. | Wear-resistant, heat-resistant, corrosion-resistant, lubricated by pump circulating water, capable of dry grinding for a short time, high requirement on accuracy in processing and assembly, fragile and the most expensive. | It has a long history and mature manufacturing process, featured by wear resistance, anti-seismic, impact resistance, convenient assembly/disassembly and low price (only 20% of ceramic bearings price) | Wear resistance and impact resistance require a set of more complicated sealing and lubricating devices and mechanisms. |

| Lubricating requirements | Clean water can be used for lubrication or 150s dry start according to the material grades. | Dry start more than 180S without clean water lubrication. | It can be lubricated by pumping medium without special clean water lubrication. | Clean industrial water | Grease lubrication requires a grease supply lubrication system. |

| Working temperature | ≤70ºC | ≥273ºC | The bearing itself can withstand the temperature of 1,400ºC | ≤50ºC | ≤65ºC Short time up to 80ºC |

| Application site | For pumping stations short of clean water or pumping stations requiring short-term dry friction, hRBR grade is suitable for water quality with moderate sediment content. | Pumping stations without clean water or pumping stations requiring dry friction of more than 180S. | Pumping stations without clean water or pumping stations requiring short-term dry friction. | Extensive application in any pumping stations with clean water sources. | The liquid of the pump itself cannot be used for bearing lubrication in the pumping station. |

| Bearing type | INDRON bearing | AR bearing | Ceramic bearing | Rubber bearing | Babbitt alloy bearing |

Related Products

-

![Wholesale Customized Precision Auto Parts Steel Bearing Flanged Oilless Sleeve Bushing Self Lubricating Bronze Bushing]()

Wholesale Customized Precision Auto Parts Steel Bearing Flanged Oilless Sleeve Bushing Self Lubricating Bronze Bushing

-

![Fb090 Bronze Wrapped Oilless Plain Bearing Custom Made Bearing Bush Bronze Bushing Oilless Bearing FB092 FB094 FB09G]()

Fb090 Bronze Wrapped Oilless Plain Bearing Custom Made Bearing Bush Bronze Bushing Oilless Bearing FB092 FB094 FB09G

-

![OEM Manufacturer Custom Metal Stainless Steel Galvanizing Steering Arm Swivel Shaft Pin Seal Bushing]()

OEM Manufacturer Custom Metal Stainless Steel Galvanizing Steering Arm Swivel Shaft Pin Seal Bushing

-

![Fb090 Bronze Wrapped Slide Bearing Bearing Bush Bronze Bushing Oilless Bearing]()

Fb090 Bronze Wrapped Slide Bearing Bearing Bush Bronze Bushing Oilless Bearing